24hr Media Fundamentals Explained

Table of ContentsNot known Facts About 24hr Media24hr Media - An OverviewThe Basic Principles Of 24hr Media Little Known Questions About 24hr Media.Top Guidelines Of 24hr Media

Improvements in print modern technology are changing the interactions playing area when it comes to quality, cost and cutting-edge abilities. Offset printing and electronic printing are the major procedures through which print tasks are embarked on both using four-color printing methods. Each alternative has its benefits, providing different strategies to satisfy the needs of varied production tasks.

Normally, this has actually been one of the most consistent strategy for precisely maintaining color suits, making it excellent for print runs that only need static printing such as pre-printed types, brochures, flyers, calling card, and mass postcard mailings. However, due to the static nature of litho printing, it is not suitable for variable print pieces that will be mailed to individual recipients such as statements, letters, and individualized postcards.

The Single Strategy To Use For 24hr Media

The most up to date innovations in print modern technology are aiding to bring a lot of balanced out's benefits right into the electronic printing world absolutely altering the face of modern-day printing! There are some key differences in between Offset Printing and Digital Printing (Window Vinyl). This overview shows the benefits and negative aspects of each printing approach. There is an undeniable and expanding variety of benefits to using the digital print procedure.

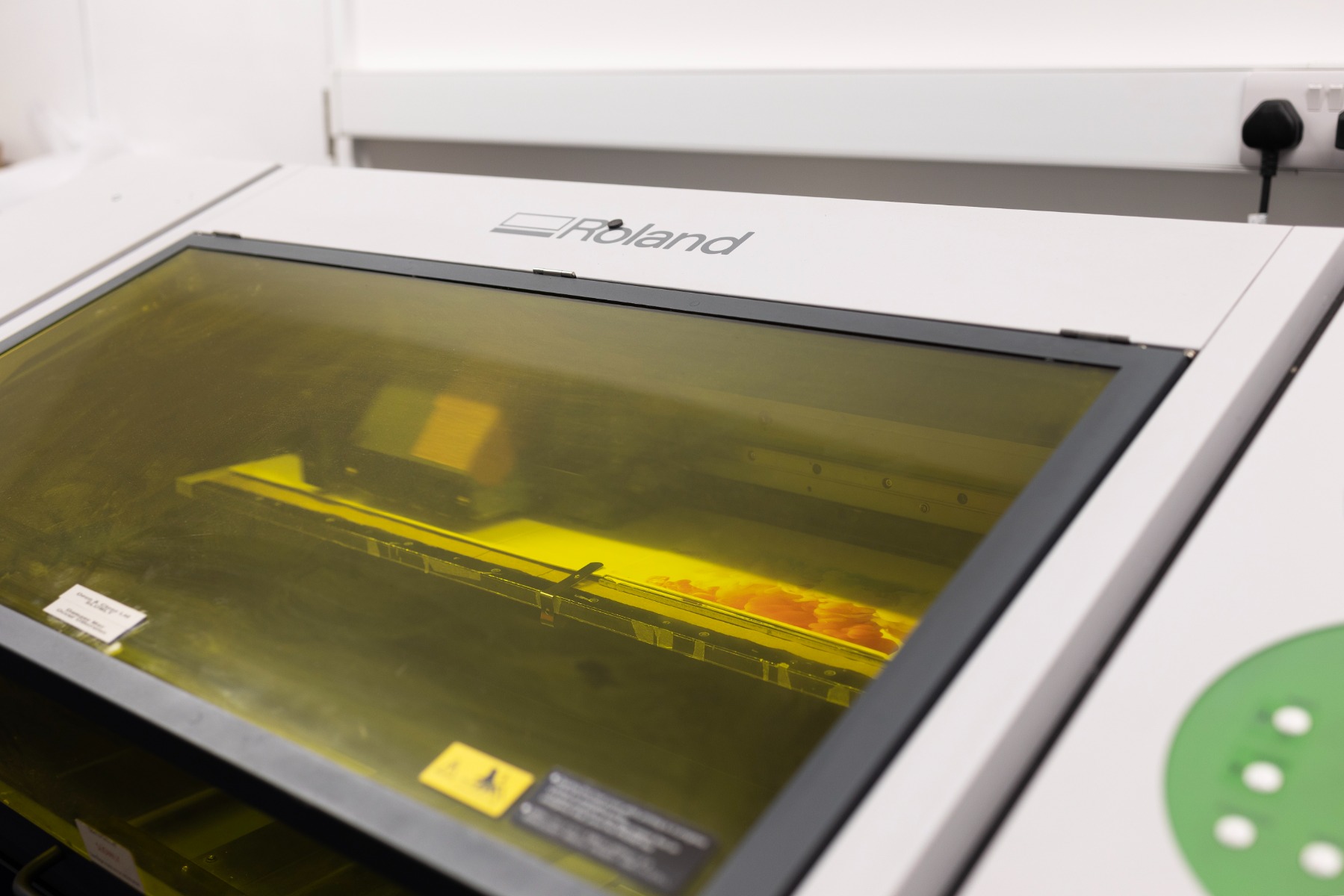

Today's digital print devices is amongst one of the most sophisticated on the marketplace. Below are several of the largest benefits of using electronic printing: dominate the digital print room, with full-color printing completed in one process and flawlessly published directly from a print data. Without an extensive set-up procedure, the calibration time of a details work is shortened, adding to quicker print time and general delivery.

The inkjet printing procedure has actually assisted to transform the sector as well as the top quality and rate of the outcome. The most recent inkjet innovation can publish on typical offset stocks with dull, silk, and shiny surfaces. High-quality digital print combined with software-managed shade monitoring methods includes optimum worth to print pieces and makes production processes more trustworthy than offset.

The 6-Minute Rule for 24hr Media

(https://24krmedia.webflow.io/)

Eco-friendly and eco-friendly inks and printer toners are likewise offered for more lasting printing. Digital print additionally eliminates the requirement to wash plates or blankets with unsafe chemicals at the end of the printing process.

Variable data assists organizations reach their exact customers and audience with uniquely-created and customized content. As technology improves, the high quality of digital printing has become second-to-none, with higher information, color match capabilities and general accuracy. Without the demand to clean plates or make use of excess ink, digital printing is additionally less inefficient and normally much more environmentally pleasant.

Conventional printing methods, such as countered lithography ("balanced out") and flexography ("flexo"), involve numerous make-ready actions to move an initial picture to a substrate. These approaches require the production of a collection of plates installed on a cylinder to transfer ink that creates the desired picture when combined on paperboard and other product packaging products. Point of sale stands.

Top Guidelines Of 24hr Media

While digital printing is a sensible option for many short-run print tasksunique celebrations, prototyping, or various other considerationsits modern-day capacities really show in fast turnarounds. Being able to personalize packaging with variable data printing has opened up new opportunities for you to involve with your clients in more individualized means. Digital printing, with fewer moving pieces, is much more active than balanced out in this respect.

It's a way to blend your product packaging and advertising and marketing great site strategies. Reduced set-up time conserves cash on the front end. And given that these are not huge bulk orders, smaller sized services can manage to print without having to fulfill the greater and much more costly print limits of traditional printing. Digital printing helps secure your brand against counterfeiting by incorporating obvious and concealed services on your product packaging.

Make sure you team up with a printing and product packaging partner that has the best certifications. While eleventh-hour printing and modification are a massive benefit, digital might not always be the best approach for you. Offset printing has the benefit of cost-effectiveness with large print runs, particularly those with innovative attractive effects and specialty coatings.

Unknown Facts About 24hr Media

The favorable plate, with its smooth surface, draws in oil-based inks and repels water. In contrast, the unfavorable plate, with its harsh structure, absorbs water and pushes back oil. Rubber rollers are then utilized to transfer the photo from the plate to the corrugated surface.

Corrugated paper can sometimes verify to be a difficult surface area to print on, yet Litho prints to a different surface and is then laminated flooring to it, making it easy to publish high-grade images. It can be very regular, also for long terms. In truth, the extra you print, the cheaper the expenses end up being for Litho.

What Litho does not give you is precisely what Digital does, modification. Pricey established up Longer turn-around No Variable Information Printing Smaller sized shade gamut, colors can be less brilliant Digital printing is the process of printing digital images straight onto the corrugated substratum making use of a single-pass, direct-to-corrugate technique.